The three-motor drive established in the FL100 has evolved and developed into a four-motor drive, and the latest in servo technology and dramatically improved CPU performance provides even greater accuracy and control. New intelligent features have been added to the FL200, enabling the machine to “think for itself” and become a detailoriented assistant facilitating the customer’s operations. Combined with the synergy of a high-performance tension controller, the FL200 guarantees our customers a roving process one rank above all others in every aspect of performance, including productivity, operability, and roving quality.

Newly Developed Four-Motor Drive

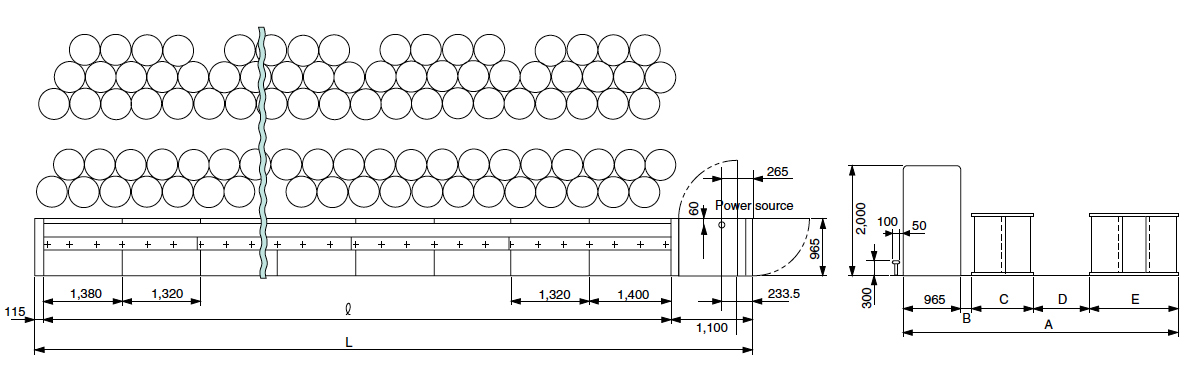

| Number of spindles / Dimensions | ℓ | L (frame length) |

| 144 | 15,980 | 17,195 |

| 132 | 14,660 | 15,875 |

| 120 | 13,340 | 14,555 |

| 108 | 12,020 | 13,235 |

| 96 | 10,700 | 11,915 |

| Dimensions / Can Diameter | 508 (20) | 508 (20) |

| A | 4,805 | 4,405 |

| B | 400 | 400 |

| C | 990 | 990 |

| D | 1,000 | 600 |

| E | 1,450 | 1,450 |

| Configuration | 5-row staggered |

(Unit: mm)

(Unit: mm)

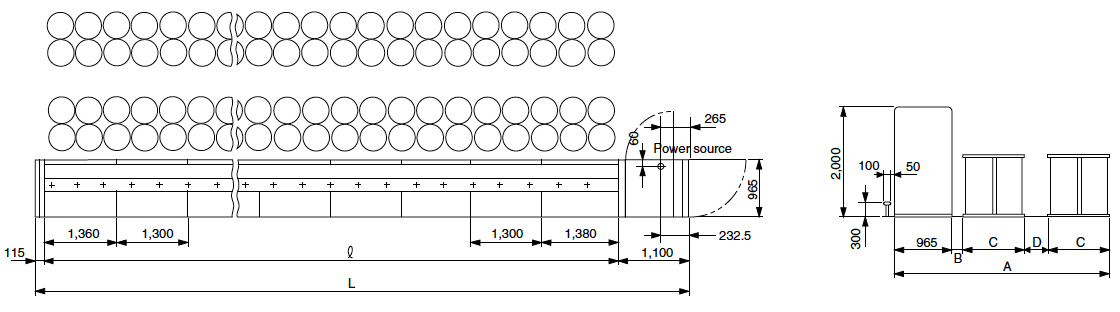

| Number of spindles / Dimensions | ℓ | L (frame length) |

| 140 | 18,340 | 19,555 |

| 120 | 15,740 | 16,955 |

| 108 | 14,180 | 15,395 |

| 96 | 12,620 | 13,835 |

| Dimensions / Can Diameter | 508 (20) | 508 (20) |

| A | 4,465 | 4,065 |

| B | 400 | 400 |

| C | 1,050 | 1,050 |

| D | 1,000 | 600 |

(Unit: mm)

(Unit: mm)

Main Specifications |

(Unit: MM) |

| Staple length | 22-40 mm | 40-51 mm | 51-76 mm | 44-76 mm* | |||||

| Drafting system | 4-roller (D type) | 4-roller (D type) | 3-roller | 3-roller | |||||

| Weighting arm | Maker | Texparts | Texparts | Texparts | Texparts | ||||

| Type | PK 1500-001938 | PK 1500-001938 | PK 1500-02 | PK 1500-02 | |||||

| Weight (kg/2 spindles) | F | 9-12-15 | 9-12-15 | 20-25-30 | 20-25-30 | ||||

| 2 | 15-20-25 | 15-20-25 | 10-15-20 | 10-15-20 | |||||

| 3 | 10-15-20 | 10-15-20 | 15-20-25 | 15-20-25 | |||||

| B | 10-15-20 | 10-15-20 | -- | -- | |||||

| Cradle type | OH514-110 | OH524-110 | OH514-110 | OH524-110 | |||||

| Cradle radius x width (mm) | 34.5 x 40 | 45.0 x 40 | 58.0 x 40 | 45.0 x 40 | |||||

| Bottom roller diameter (mm) | F | 28.5 | 28.5 | 31.75 | 31.75 | ||||

| 2 | 28.5 | 28.5 | 28.5 (knurled) | 28.5 (knurled) | |||||

| 3 | 28.5 (knurled) | 28.5 (knurled) | 31.75 | 31.75 | |||||

| B | 28.5 | 28.5 | -- | -- | |||||

| Top roller diameter (mm) | 28 | 28 | 35 | 35 | |||||

| Roller gauge (mm) | F-2 | 35 - | Max. 193 (total) | 42- | Max. 193 (total) | 73- | Max. 185 (total) | 62- | Max. 185 (total) |

| 2-3 | 4-7 | 60- | 57- | 52- | |||||

| 3-B | 45- | 49- | -- | -- | |||||

| Clearer | Positive intermittent revolving clearer with comb | ||||||||

| Feeding can | Up to 508 mm (20") diameter x 1,150 mm (45") high | ||||||||

| Creel | Positive revolving feed roller with extended creel (single sliver feed system) | ||||||||

| Power Required | Main motor: 15kW | ||||||||

| Special devices (included) | Height speed | Automatic flyer speed control with inverter | Toyota original High Speed Flyer | ||||||

| Quality | Automatic tension controller, roving irregularity prevention, roving stop at set length/position, package shoulder collapse prevention, optical electronic roving stop motion, optical electronic sliver stop motion, stop motion upon roving breakage at middle part of package | ||||||||

| Operation and maintenance | 10.4-inch color function panel, bobbin misplacement prevention device, automatic grease lubrication for draft gearing, automatic grease supply system for flyer gear, clearer waste collector (pneuma-less type) | ||||||||

| Automation | Automatic roving-end positioning for machine restart, high-twist roving cutting device | ||||||||

| Options | High speed | Bobbin jumping prevention device | |||||||

| Quality | Creel tension fine adjustment mechanism | ||||||||

| Operation and maintenance | Flyer-rail cover cleaning device, automatic travelling suction cleaner, TMS |

For countries outside the U.S., please click the below link to reach an agent in your area.

https://textile-machinery.toyota-industries.com/